Products

Tube bending tools from the experts

Tube bending tools made of high-strength aluminum bronze and tool steel

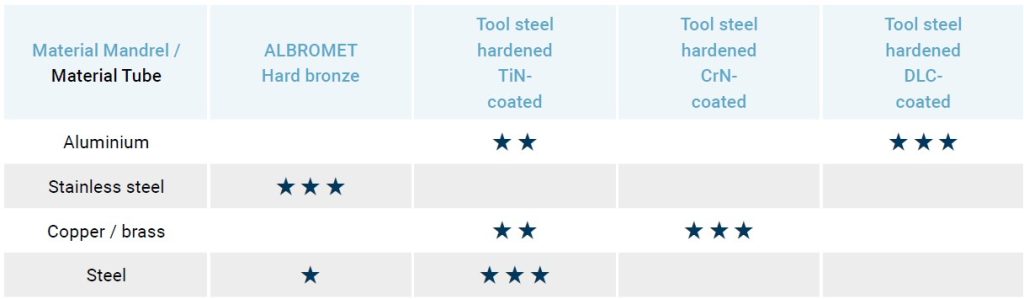

Depending on the application and pipe material, ALBROMET offers pipe bending tools made of aluminum bronze and tool steel. Bending mandrels, flatteners and flattener shells in particular are produced in-house. We attach great importance to the highest material quality in order to minimize wear. All tube bending tools are manufactured according to customer drawings or developed and designed in-house at ALBROMET.

As a manufacturer of tube bending tools, we place the highest value on function and design. The bending process is simulated using CAD and checked for function and collision. Most tools are made of hard aluminum bronze, which gives them very good formability.

For other applications, such as bending non-ferrous metals, tube bending tools are produced from steel with a coating to suit the application. The high-precision connecting links between the shank and balls are made of high-strength, top-quality tool steel.

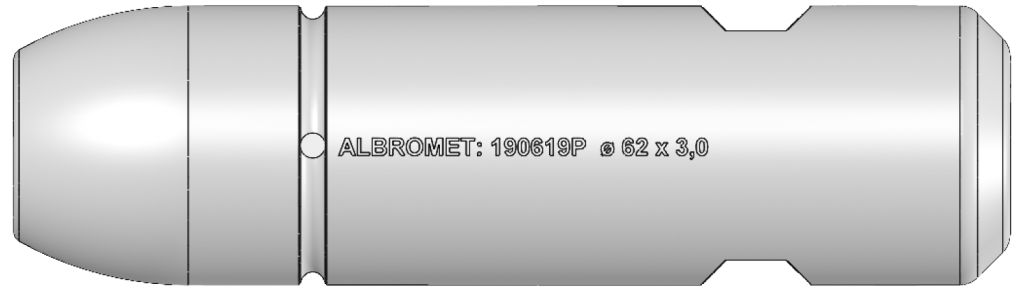

Our bending mandrels with the best surface quality and strength achieve a high bending quality. They offer a long service life and are easy to replace with ALBROMET spare part sets when servicing is required. Depending on the bending task and requirements, we offer system link mandrels, stub mandrels, bucket mandrels and mandrels for minimum quantity lubrication.

That speaks for our tube bending tools:

- Consistently high bending quality

- Workpieces retain their shape

- Universally applicable

- Collision-tested with CAD technology

- The links reset themselves by spring force

- Long service life with quickly replaceable spare part sets

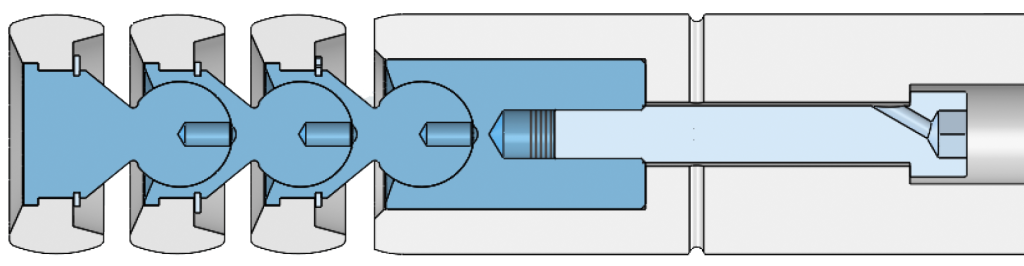

System link mandrels

Resetting is effected by the spring force of the links. All spare parts are individually replaceable.

- Standard system link mandrel

- sd® with ball distance reduced by 40%

- xsd® with ball distance reduced by 80%

- MQL for minimum quantity lubrication

- MQL for LBI oil free lubricants

Bending mandrels in special designs

For pipes with thick wall thicknesses or a

Diameter / wall thickness ratio >10% we offer further mandrel variants.

- Plug mandrels

- Spoon mandrels

Wiper dies and wiper die inserts

With the best elongation at break values > 16% and very good sliding properties (Ni-free alloy), they support the bending process.

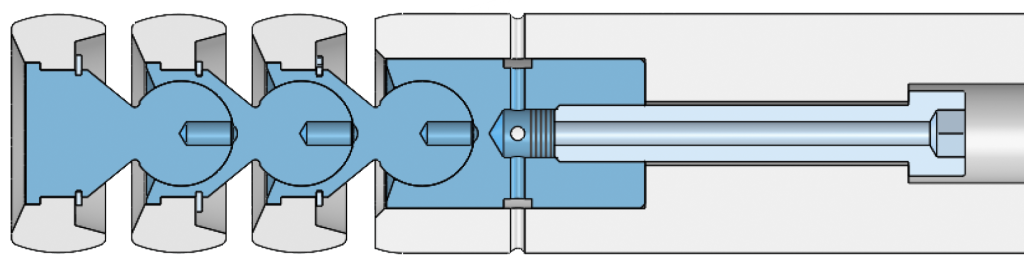

Design of system link mandrel

Standard system link mandrel – with NORMAL LUBRICATION

- Fast delivery time

- Favorable price

Standard system link mandrel – with MMS (MINIMUM MEASUREMENT LUBRICATION)

- Low lubrication consumption

- Lubrication distribution closer to the bending area

- Better oil distribution through compressed air injection of fluids

- Compatible with lubrication systems from LBI oil free

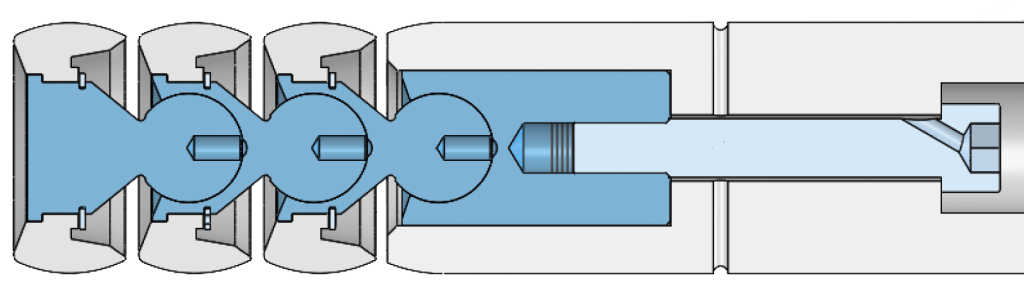

SD version “small distance” (normal lubrication and MQL)

- Ball distance reduced by 40%

- Larger contact surface

- Crease-free bending for thin-walled pipes

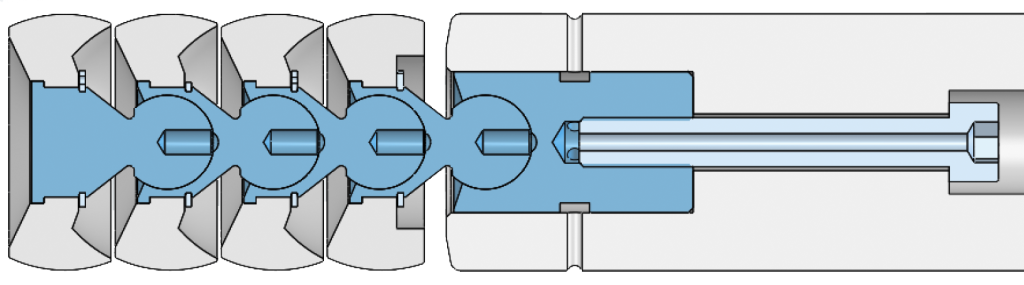

X-SD version “extra small distance”

(normal lubrication and MQL)

- Ball distance reduced by 80%

- smaller connecting links

- for extremely thin-walled pipes

- for the most difficult bending tasks

Plug mandrel

- For pipes with thick walls or

Diameter / wall thickness ratio >10% - available from ALBROMET in all variants.

Spoon mandrel

- For pipes with thick walls or

Diameter / wall thickness ratio >10% - 3D-milled contour in the bending area

- therefore large contact surface

- therefore perfect bending result

- available from ALBROMET in all variants

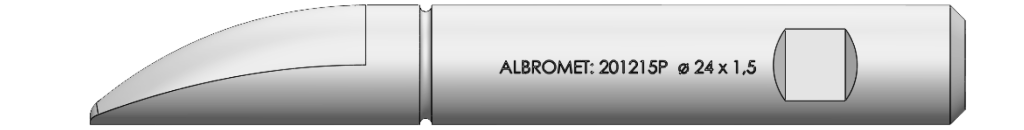

Wiper dies and wiper die inserts

Straighteners prevent irregular compression of the pipe during the bending process, as they support the pipe in the inner bend. The shape and material are individually adapted to the bending tube. ALBROMET designs and manufactures crease smoothers, crease smoothing trays and rectangular crease smoothers.

- Made of Albromet aluminum bronze

- made of tool steel

- Coating according to application

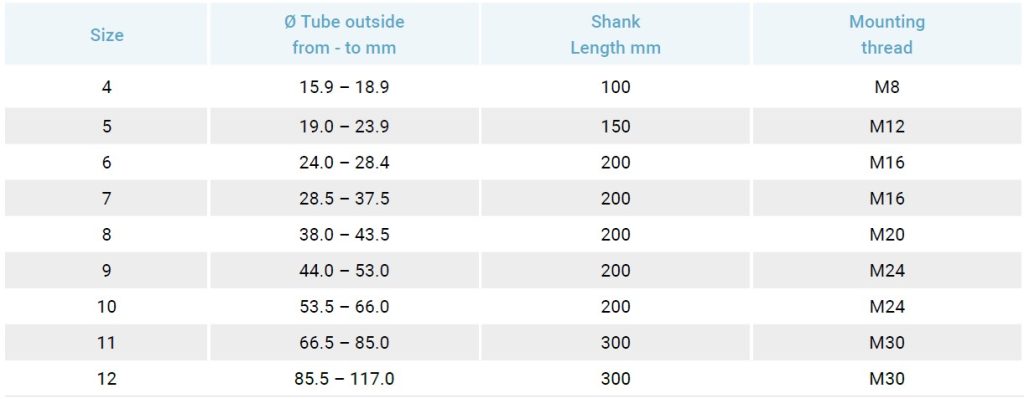

Design aids for system mandrels

The size of the bending mandrel is defined by the outer diameter of the pipe. The bending tool material is selected to match the pipe material. Use our design guide and the appropriate inquiry forms!

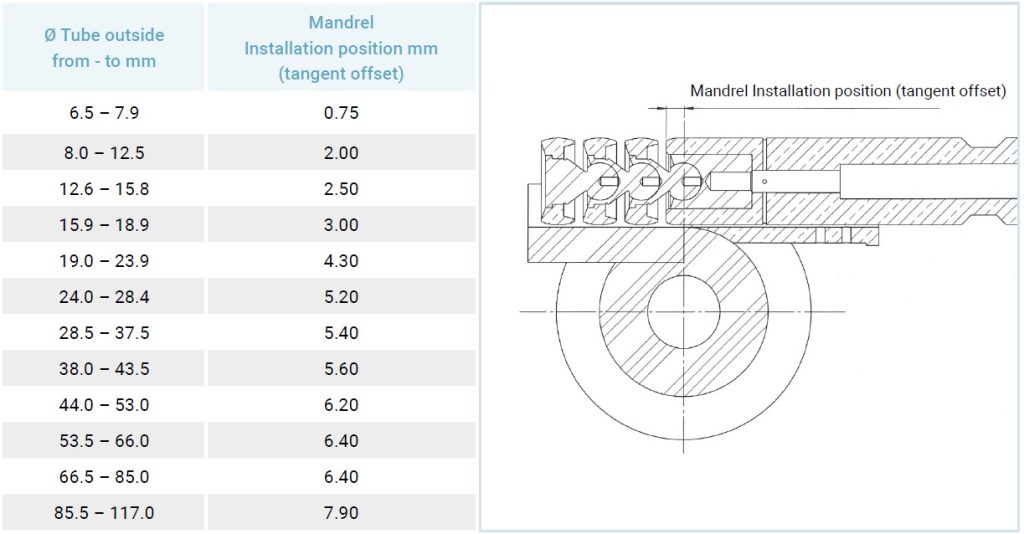

The diagram below shows the recommended installation position of the system arbor. Fine adjustment should be made after analyzing the bent pipes.

Connecting links for system link mandrel incl. Accessories

The high-precision connecting links between shank and balls are made from a heat-treated tool steel in premium quality with extremely high strength. This increases the service life and reduces operating costs during use. Thanks to our in-house production, we offer a very good price-performance ratio. The connecting links are available from stock as spare parts from ALBROMET.