Products

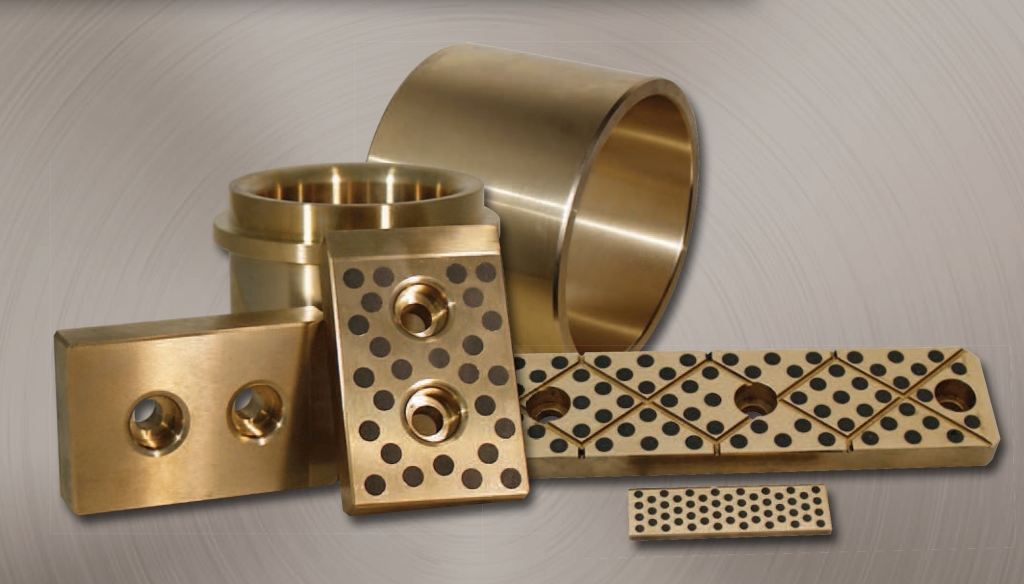

Sliding bushes, sliding plates &

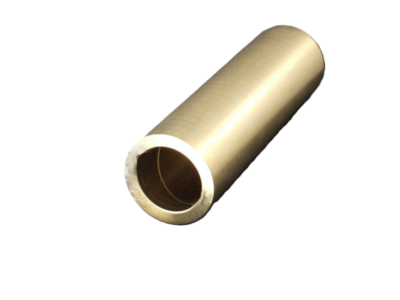

Guide bushes

Manufacture from hard bronze in special sizes and shapes

The best guided tours are the ones you don’t have to worry about. Guide bushings, plain bearings and sliding plates made from our high-strength aluminum bronze have excellent sliding properties, high strength and outstanding emergency running properties.

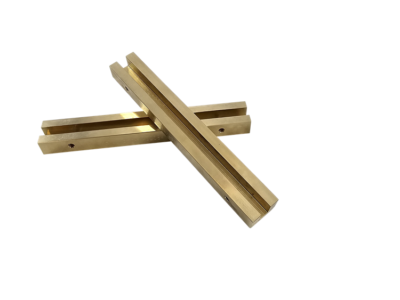

As a specialist for guide and sliding elements, we attach great importance to precise production in order to minimize play and ensure exact guidance. Correct lubrication reduces friction and extends service life. We manufacture for you in special sizes and shapes according to drawings from a quantity of 1 to series production.

- Cylindrical sockets: standard version, easy to install

- Flange bushings: With a flange for axial positioning and support

- Sliding plates: Flat plates for linear movements

- Segmented plain bearings: For large and heavy applications, such as turbines or large machines

- Ball cup bearings: For applications with swivel movements

- Self-aligning plain bearings: Allow a certain freedom of movement and compensation for misalignment

Thanks to their high corrosion resistance, ALBROMET aluminum bronzes can also be used for sliding plates and guide bushings that come into contact with industrial water, seawater or chemicals. The aluminum bronzes ALBROMET-A200 and A260Ni as well as the high-strength copper alloy W200 are also certified for use in direct contact with food. We use them to manufacture your sliding elements for food technology according to drawings.

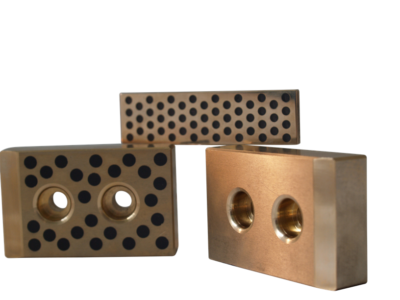

Self-lubricating or dry-running sliding elements - also for food technology

Graphite balls or Teflon balls can be embedded in the aluminum bronzes for dry running or low-lubricant operation. These can be installed in the components as required by the customer. We will provide you with a design and recommendation based on your component drawing.

The aluminum bronzes ALBROMET-A200 and A260Ni as well as the high-strength copper alloy W200 are certified by an independent testing institute for use in direct contact with food. If our certified plastic beads (Teflon) are used as sliding elements, the guide bushes and plain bearings manufactured with them are also approved.

Sliding bushes - An offer from ALBROMET

The ALBROMET team supports you with the design and manufacture of sliding elements and guide bushes according to your specific requirements. There are no limits to the design of shape, size, lubrication grooves, lubrication pockets and lubrication channels. The material is selected according to the friction partner. Simply send us your drawing and requirements! We will prepare an offer at short notice.

Advantages of ALBROMET aluminum bronzes:

- Very good sliding properties

- High compressive strength

- Minimized friction due to smooth surfaces

- Very good emergency running properties

- High resistance to shocks and vibrations

- Corrosion-resistant to many media

- Also available as components for dry running

- Special dimensions according to drawing are manufactured from quantity 1

Answers to frequently asked questions

Aluminium bronzes are used in all machines and systems in which the friction of moving parts is to be minimized. They are the ideal friction partner for all types of steel. Both strength, modulus of elasticity and compressive strength are very high. With good lubrication, friction and wear are very low. Adhesion does not occur when paired with steel due to the different materials, which also means good emergency running properties. The heat generated by friction is dissipated well due to the high thermal conductivity of aluminum bronzes.

Plain bearings in machines usually need to be lubricated to ensure their functionality and increase their service life. However, there are also special maintenance-free variants that do not require additional lubrication. The choice of the appropriate bearing and lubrication method depends on the specific requirements of the application, the operating environment and the maintenance requirements. A distinction is made between dry-running bearings, solid lubricant bearings and lubricated plain bearings with continuous oil lubrication via lubricant pockets.

Lubricants reduce the friction between the bearing surfaces and the moving parts, which increases the efficiency of movement and reduces energy consumption. Lubrication minimizes direct contact between the metal surfaces, which reduces wear and extends the service life of the bearings and the machine. Lubricants also help to dissipate the heat generated by friction, which prevents bearings from overheating and therefore avoids damage caused by thermal stress. Finally, lubricants provide some protection against corrosion and rust formation by shielding the metal surfaces from moisture and other corrosive substances.

Compared to rolling bearings (ball bearings or roller bearings), plain bearings have a number of advantages that make them particularly suitable for certain applications.

- Plain bearings have a simpler design without moving parts such as balls or rollers. They mainly consist of a bearing bush and a shaft. As a result, plain bearings are generally cheaper to manufacture and purchase than roller bearings.

- Plain bearings can distribute high loads evenly over a large area, thus avoiding point loads. They are less sensitive to shocks and impacts, which makes them particularly suitable for applications with alternating or shock loads.

- Plain bearings require less installation space than rolling bearings, as they do not need additional components such as cages or rolling elements.

- Slide bearings can be more easily adapted to specific spatial requirements.

- Plain bearings are also available as low-maintenance variants with self-lubricating materials such as PTFE (Teflon) or impregnated with solid lubricants.

The manufacture of plain bearings involves various techniques and processes that make it possible to produce bearings with different properties, shapes and sizes. The following process selection is defined by the material used:

- Casting

- Sintering

- Mechanical processing (solid plain bearing)

- Extrusion

- Rollers

- Injection molding

- Coating

- Additive manufacturing (3D printing)

ALBROMET specializes in solid plain bearings made from aluminium bronze and copper alloys. These normally consist of a single bearing material. Plain bearings are often provided with lubrication grooves, pockets or channels. Oils, greases or oil-free lubricants are used for lubrication (see also our cooperation with LBI oil free).

Get in touch with us!

We will advise you competently and personally.