Products

Copper alloys from ALBROMET - conductive and high-strength

Low-alloy copper alloys - a highly developed material

ALBROMET offers a wide range of highly conductive copper alloys. Alloying elements such as nickel, cobalt, silicon, beryllium and chromium give these alloys unique combinations of properties that are very valuable in many areas of application. The materials are thermally hardened and combine very good electrical and thermal conductivity with excellent mechanical properties and good corrosion resistance.

These alloys are mainly used in plastic mold construction, in forming technology, in the steel industry or as an electrode material for resistance welding, where the very high thermal conductivity or electrical conductivity are of primary importance.

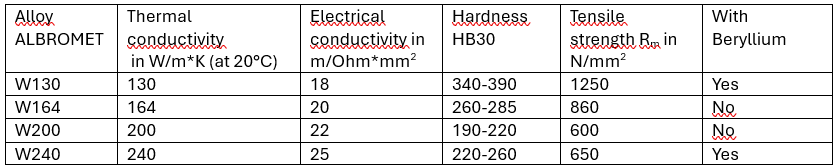

The low-alloyed copper alloys offer very high strength values (Rm) of up to 1250 N/mm² and hardnesses of 200 – 390 HB. At the same time, the thermal conductivity of 130 – 260 W/m*K (at 20°C) is up to 12 times higher than that of stainless steel. In general, thermal conductivity decreases with increasing hardness.

The compressive strength and modulus of elasticity (135 – 140 kN/mm²) of these copper alloys are comparatively high compared to brass (100 kN/mm²) or stainless steels (200 kN/mm²). Their excellent media resistance also makes them attractive as sealing rings.

Properties and characteristic values of ALBROMET copper alloys

You can find all characteristic values here:

The detailed data sheets for all alloys can also be found in our media library.

Our copper alloys are available in stock as cast, pressed or forged semi-finished products in various shapes (round, plates) and dimensions. See our comprehensive product range for yourself.

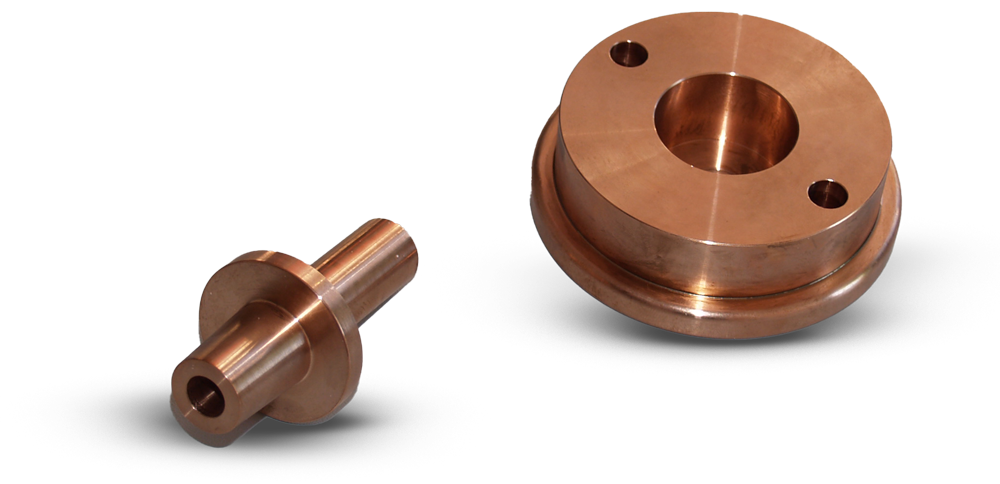

ALBROMET supplies semi-finished products cut to your desired dimensions in our cutting center. With an extensive range of machinery, we also manufacture finished parts according to your drawings from all the copper alloys mentioned, starting from a quantity of 1. This gives you the advantage of reducing the burden on your own production and minimizing procurement costs. Simply ask for a non-binding offer!

Beryllium-free copper alloys

With the alloys ALBROMET-W164 and ALBROMET-W200, the ALBROMET product range includes two beryllium-free copper alloys with very high strength values and very good wear resistance.

With strength values of up to 860 N/mm², these alloys achieve similar values to beryllium-containing alloys and, with their excellent thermal conductivity, have been developed as a replacement for copper-beryllium alloys in the high-end sector.

Why are beryllium-free alloys interesting?

Beryllium ensures very good strength through a hardening process. However, safety measures must be observed when machining or welding alloys containing beryllium. These measures include special ventilation systems, personal protective equipment and regular health checks for the workers. For this reason, beryllium-free copper alloys are preferred as alternative materials where possible. There are no restrictions on the use of machined components made from beryllium-containing alloys.

Beryllium is not on the list of hazardous substances according to REACH.

Copper alloys with food certification

ALBROMET has received a declaration of no objection from an independent testing institute for the following copper alloy for use in direct contact with foodstuffs in accordance with EU Regulation 1935/2004. This alloy is therefore also ideal for use in the food technology and packaging industry and combines high wear resistance with very good thermal conductivity.

Frequently asked questions

For copper alloys, the number after the “W” stands for the thermal conductivity at 20° C in W/m*K.

The thermal conductivity (SI) of copper alloys is usually measured in W/(m*K). This is a material property and reflects the heat transport within this material. The higher the number, the higher the transport capacity.

The terms conductive copper or highly conductive copper alloy describe the property of being able to conduct heat or electricity very well. These properties are used particularly in plastic mould construction and extrusion technology, as mould inserts and mould cores to optimize cycle times and product quality, as well as in numerous other components such as nozzles and blow moulds. These alloys are also used as welding mirrors, tempering elements and electrodes in resistance welding and in mechanical engineering as a whole.

Copper alloys are generally non-magnetic. Pure copper is a non-magnetic metal. If copper is alloyed with other metals, such as with zinc to produce brass or with tin to produce bronze, the alloy also remains non-magnetic in most cases. This is because the added metals are also non-magnetic.

However, some special copper alloys can have magnetic properties if they contain iron or nickel. These metals are ferromagnetic and can influence the magnetic properties of the alloy.

ALBROMET copper alloys are therefore largely non-magnetic, which has advantages in many applications. Chips and metallic dust do not stick. In addition, there is usually no sparking.

Resistance welding is a process in which electrical currents flow through the parts to be joined in order to generate heat and melt and join the material at the joint. Copper and its alloys have excellent electrical and thermal conductivity. These properties enable efficient heat transfer to the welding point, which promotes the formation of a strong and reliable welded joint.

For this reason Copper alloys are very suitable for resistance welding due to their excellent electrical and thermal conductivity as well as their wear resistance. Their high resistance to mechanical wear and sparking also makes them ideal for use in electrodes for resistance welding.

ALBROMET copper alloys do not contain any hazardous substances on the REACH candidate list (SVHC list). The lead content is minimal (< 0.1 percent by mass). This means that the copper alloys are REACH and RoHS compliant. You can find more information here.

Copper alloys are usually produced using traditional smelting processes and further processing of continuous cast billets in forges and press shops. ALBROMET sources the copper alloys mainly in Europe and North America. The ALBROMET warehouse stocks a wide variety of dimensions of round material and sheets, which can be cut to size at short notice.

Get in touch with us!

We will advise you competently and personally.