Increase productivity in plastic molding

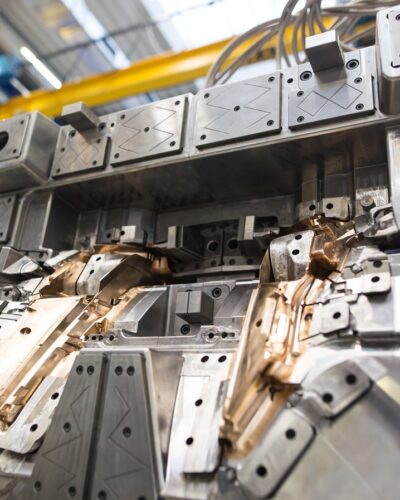

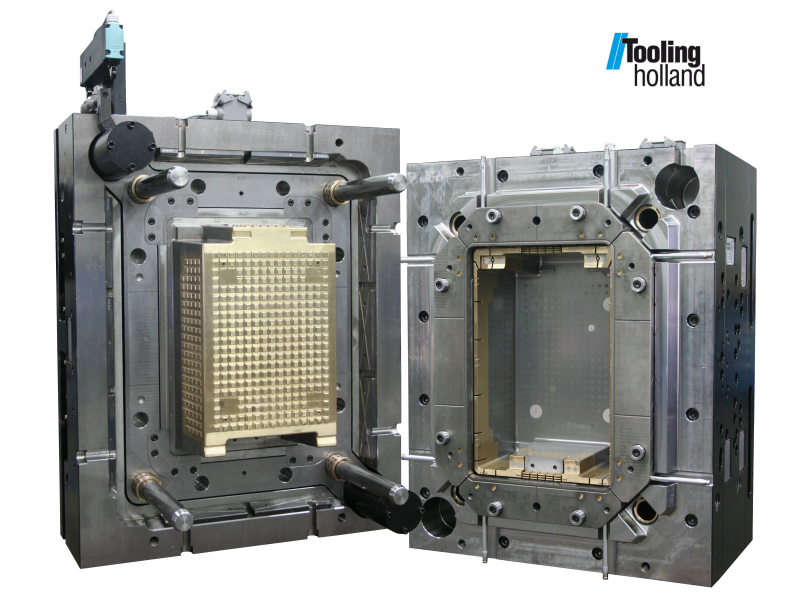

ALBROMET offers high-strength copper alloys with very good thermal conductivity and high wear resistance especially for mold making in plastics technology. The excellent polishability and very low adhesion tendency increase the quality of the manufactured plastic parts and facilitate demolding. In addition, the very good thermal conductivity enables a high tempering speed and rapid cooling. The even heat distribution in the mold ensures shorter cycle times and significantly improves the surface of the injection-moulded and blow-moulded plastic parts.

The ALBROMET product range includes beryllium-free copper alloys with very good strength values and high-strength CuBe alloys for mold and tool making.

Einsätze in Spritzformen werden oft aus Aluminiumbronzen gefertigt. These support good demolding in conjunction with good heat conduction. ALBROMET’s wear-resistant aluminum bronzes can also be used to produce low-friction and durable sliding elements such as plates, bushings and guide rails for plastic machines.

ALBROMET’s aluminum bronzes and copper alloys are RoHS and REACH compliant.

Your advantages

- Very high thermal conductivity

- Excellent sliding properties

- High temperature resistance

- High strength

- Long service life

- Low surface roughness and good polishability

The copper alloys can be coated to increase the surface hardness. This reduces wear due to abrasion and the tendency to stick. Demolding is simplified and the service life of the tools is extended.

The very good thermal conductivity of the copper alloy is not reduced by the very thin coating.

Components in plastics technology

- Inserts for plastic molds

- Molded cores and plates

- Guides and guide bushes

- Toothed and worm gears

- Sliding plates

- Matrices and ejectors

Get in touch with us!

We will advise you competently and personally.